AN ISO 9001:2008; ISO 14001:2004 & OHSAS 18001:2007 CERTIFIED ORGANIZATION

- Contact us:

- +91-712-2564285 (India)

- +1-404-247-9823 (USA)

- info@3achemie.co.in

Hazardous Reactions

Hazardous reaction capabilities at 3A Chemie:

| Hazardous Reactions | Reagents |

| Azide chemistry | NaN3, organic azides |

| Bromination | Br2, POBr3, PBr3, NBS, DBDMH |

| Chlorination | Oxalyl chloride |

| Cyanation | NaCN, HCN (in-situ) |

| Dehydration | P2O2, PPA |

| Diazo compound | Nitrous acid (HONO) |

| Hydrazine chemistry | NH2NH2, alkylhydrazines |

| Hydride reduction | LiAH4, NaH |

| Iodation | I2, Nal, ICL |

| Methylation | Me2SO4, Mel |

| Nitration | Conc HNO3, HNO3/H2SO4, glacial HNO3/AcOH |

| Nitro alkane reaction | MeNO2, EtNO2 |

| Organometallic chemistry | Grignard, BuLi, HexLi, LDA, Li, LiAmide |

| Organometallic chemistry | Grignard, BuLi, HexLi, LDA, Li, LiAmide |

| Oxidation | HNO3, KnMO4, mCPBA |

| Miscellaneous reaction/reagents | Chloroacetyl chloride, Alkyl mercaptans, Acetyl chloride, acetic anhydride |

Hydrogenation

3A Chemie has experience in carrying out hydrogenation using various catalysts like Palladium on Charcoal, Platinum on Charcoal, and Raney Nickel. Small scale hydrogenation reaction can be carried out at up to 50 bar pressure, with temperature between 25 to 250 °C. The reactor capacities for small scale operations are 1L, 2L and 20L

Our plant carries out hydrogenation reactions at a commercial scale at 15 bar pressure, with temperature between 25 to 150 °C. The operating capacity is 1000 L & 3000L. We undertake development projects on Hydrogenation Reactions and Contract Manufacturing of Hydrogenation Products.

Some of the our Hydrogenation Reactions carried are:

- Reduction of Aromatic Nitro.

- Reduction of Aliphatic Nitro.

- Reduction of Benzaldehydes

- Reduction of Nitriles

- Reductions of Ketones

- Reductive Amination.

- Reductive Alkylation

- Benzene Ring Hydrogenation.

- Pyridine Ring Hydrogenation

- Debenzylation

Process Intensification

Micro process technology enables new pathways for the development of economical, innovative and intensified processes in the chemical industry. Modular microreaction technology provides clear advantages over conventional process technology through

- Short mixing time

- High heat transfer rates

- Inherent safety of small hold-up

- Precise control of reaction time and

- Faster scale-up/time-to-market.

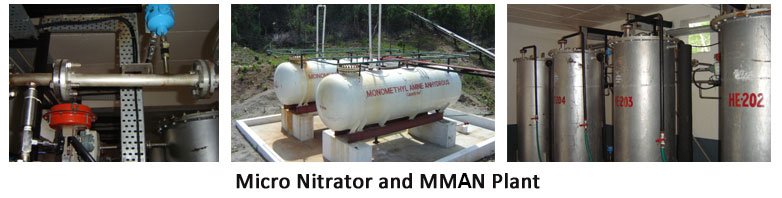

3A Chemie has experience in continuous reactions using micro and tubular flow reactors. For fast hazardous reactions in particular (e.g., nitration, nitrate ester formation, highly exothermic reactions) continuous processing enables the reduction of critical volume while simultaneously increasing the heat exchange capacity. The narrow temperature profile in continuous reactors improves reaction selectivity and enables safe execution of hazardous reactions. 3A Chemie has successfully set up 2Ethyl Hexyl Nitrate (2EHN) and Mono Methylamine Nitrate (MMAN) plant using continuous flow tubular reactors.

Copyright © 3A Chemie Pvt. Ltd. 2015-2016